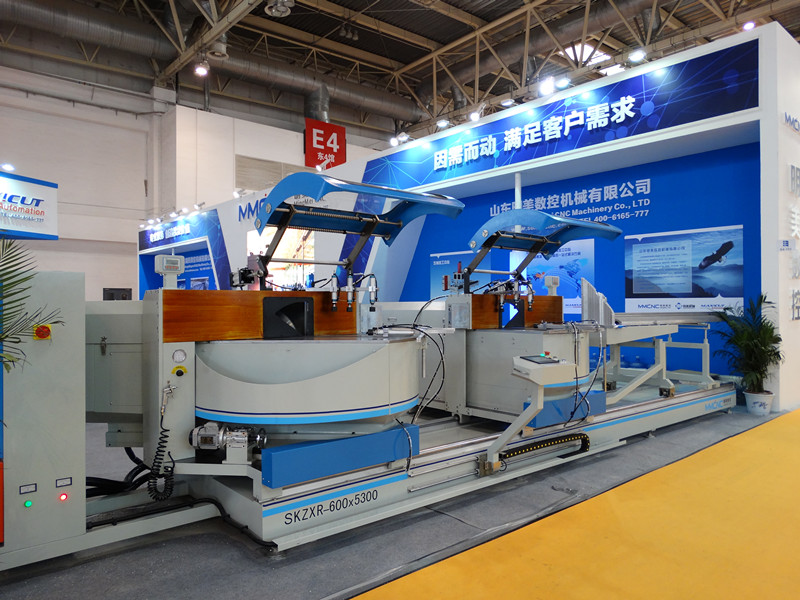

Big Profile Cutting Saw

Brand : MMCNC

Product origin : China

Delivery time : 7~30days after got deposit

Supply capacity : 30 Set Per Month

It is mainly used for processing of extra-wide aluminum profile,also can be used to process aluminum profile vertical end-face material-discharging.Adopt servo motor to drive reducer,implement saw blade rotating positioning at any angle between 45° and 90°.

1 Equipment Fearure

1.1 It is new designed to meet the development of modern aluminum curtain wall ,

aluminum template processing industry and radiator industry.

1.2 It is mainly used for processing of extra wide aluminum profile, also can be used to

process aluminum profile vertical end face material discharging.

1.3 Adopt servo motor to driver reducer, implement saw blade rotating positioning at any

angle between 45 °to 90°.

1.4 Two cutting head can swing positioning at any angle between 45° and 90°.

1.5 Two cutting heads not only can work separately, movable head feeding material

continuously , fixed cutting head cutting circularly: but also can work simultaneously , can

cut needed length and profile two ends angle at one time.

1.6 Hard alloy teeth cutting blade, high cutting speed, high produce efficiency,high

process accuracy.

2 Big Profile Cutting Saw Specifications

2.1 Power supply : 3 phase 4 wire 380V 50 Hz

2.2 Cutting head motor: 2X3 KW

2.3 Working air pressure: 0.5~0.8Mpa

2.4 Rotate speed: 2800 r/min

2.5 Saw blade swing angle servo motor power: 2X0.9KW

2.6 Cutting head horizontal move servo motor power: 1.5 kw

2.7 Saw cutting length: max 5300mm

2.8 Saw cutting width and height : max 500X180 mm in 90°

2.9 Saw cutting height: max 210mm in 90°

2.10 Saw cutting angle blade 45°~90°arbitrary angle

2.11 Cutting feed speed : stepless speed regulation 0~3m/min

2.12 Blade specification: φ600X4.4 Xφ30mm Z=120

2.13 Overall size 7500x2450x1700mm

2.14 Weight:about 5000kg

3. Machine Detailed Photos

![1]SVCLU4SXA~P7(P242E4SF.png 1]SVCLU4SXA~P7(P242E4SF.png](https://img.waimaoniu.net/488/488-201801041011290423.png)

4. Machine Package and Delivery

5.After-Service

1.One year free warrantly

2.Enjoy lifelong maintenance

3.Professional service team to provide 365 days and 24 hours of technical support

4.On-line remote service

6.Our factory

7.FAQ

♣1. When can we arrange shippment?

We usually arrange shippment within 15 days after getting deopsit,

but customized machines should be more than 25 days.

♣2.What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can send our engineers to repair your machines

♣3.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.