Aluminum 4 Axes CNC Machining Centres

Brand : MMCNC

Product origin : China

Delivery time : 60 Days after got deposit

Supply capacity : 10 Sets per month

Aluminium 4 Axis CNC Drilling Milling Machine is mainly for drilling and milling different type holes on Aluminium profile.

1. Equipment Feature

1.1 Adopt PA control system with clear interface and easy operating.

1.2 With professional windows and doors CAM software, according to the settings, the

fixture automatically placed automatically move to achieve high-efficiency three-

dimensional four-axis processing.

1.3 CAD graphics can be directly input into the system, and can also directly draw

graphics on the system CAD platform, generate NC files, edit and implement processing

programs.

1.4 Single positioning and double positioning design, up-load and down-load profile

non-stop machine, with higher processing efficiency

1.5 Centralized lubrication using intermittent supply system, the tool cooling used to the

spray pump cooling device by system control.

1.6 Can be processed aluminum, aluminum-wood composite profiles, copper and other

light metal processing

1.7 One time clamping, multi-faceted profile to complete drilling, tapping, chamfering,

milling slot and shaped hole processing

1.8 The magazine capacity is two groups of 16 knives, one for the servo disc magazine

with 8T and the other for the straight magazine with 8T.

1.9 The head adopts fully enclosed safety structure to ensure the safety of operators.

2. Parameter

Voltage | 220V/60HZ |

Air pressure | 0.6~0.8Mpa |

Total power | 16kw |

X-axis max speed | 50000mm/min |

Y-axis max speed | 30000mm/min |

Z-axis max speed | 20000mm/min |

Working Size | (X,Y,Z)7000*450*300mm |

Cutter handle model | ISO 30 |

Cutter magazine | 16cutter positions(8 as Disc type, 8 as linear type) |

Type of clamping | pneumatic clamping ( 8 ) |

Lubrication system | Automatic |

Cooling system | spray pump |

CAM software | Aluminum Window-door processing software |

Spindle | 9kw ; 0~24000rpm; air-cooling type |

Overall dimension | (L*W*H) 9000*2230*3060mm |

3. Main Component information:

Control system | DAZU(Germany PA control software) |

Spindle | Italy 9.6KW HSD brand |

Servo system | Japan YASKAVA servo driver and motor |

Solenoid valve | Taiwan AirTAC brand |

Linear guide | Taiwan ABBA brand |

electric breaker | French Schneider brand |

Ball screw | Taiwan ABBA brand |

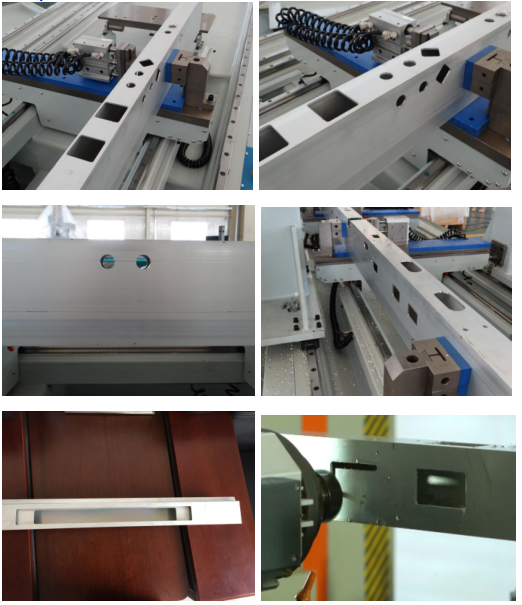

4. Aluminum 4 Axis Machining Center sample after milling

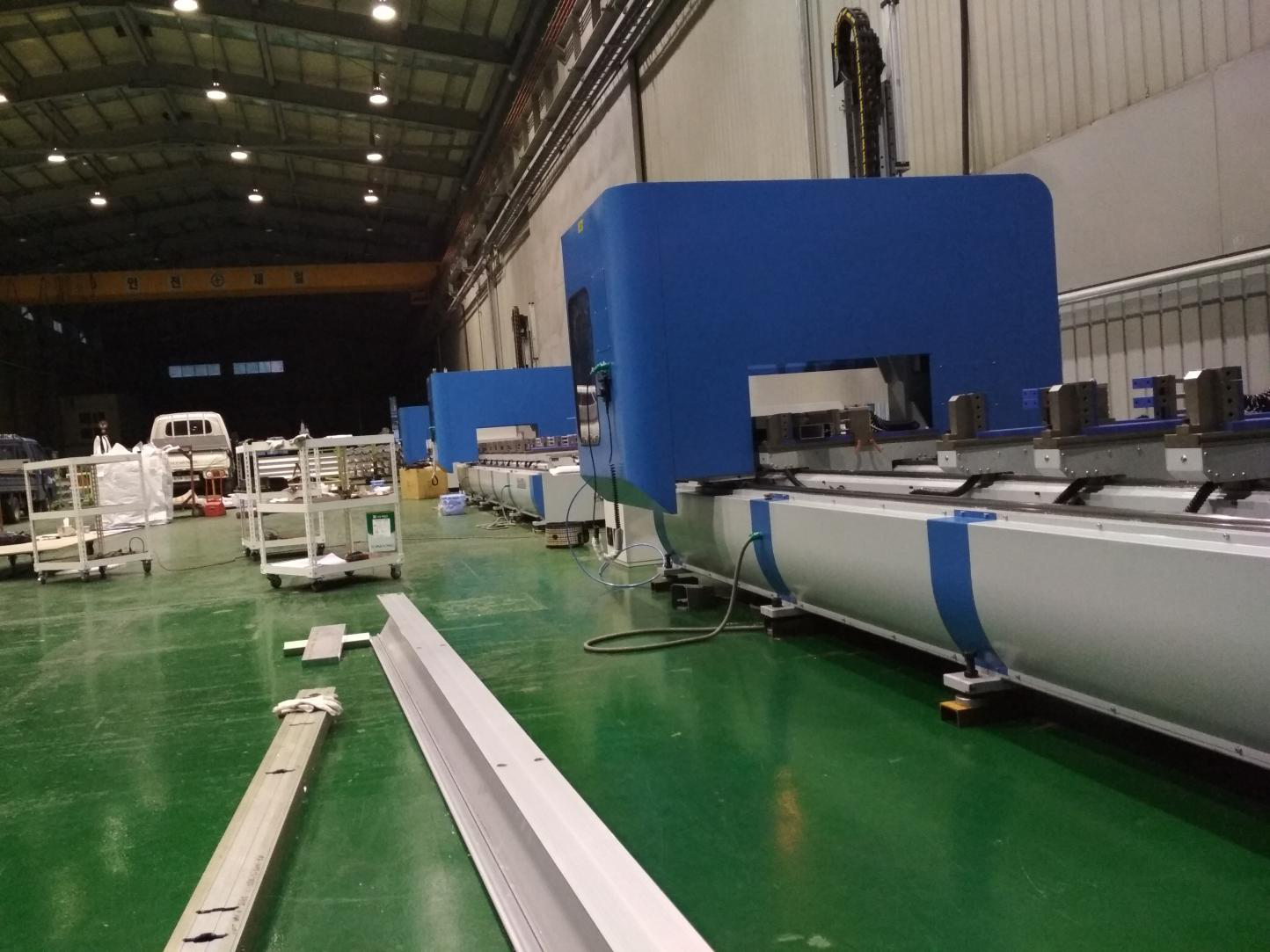

5. Machine During Delivery

6. Our Sale Team welcome your inquiry for details

7. Our Cooperation Partner

8. Aluminium Machine approved Certification

9. Our Factory

10. CNC Aluminum Machine During Loading Container

Welcome your inquiry, We will provide you the best service